Factory source Pp Film Blowing Machine - Polyvinyl Alcohol – Haitung

Factory source Pp Film Blowing Machine - Polyvinyl Alcohol – Haitung Detail:

PRODUCER:SINOPEC

PVA has many exceptional properties such as water solubility, fiber-forming property, adhesiveness, film-forming property, emulsion stability, dispersion stability, resistance to oil, acid, and alkali, chemical reactivity, biodegradability, as well as meltability (or thermoplasticity) and many unique and special properties through modification.PVA is widely used in many industries like textile, papermaking, construction, chemicals, printing, packaging, pharmaceuticals, detergents & cosmetics, agriculture, ceramics, iron & steel, electronics, electrolysis, electroplating, and etc.

Application:

PVA, which is excellent in colloid protection and has superior surface activity, is often used as dispersion stabilizer for suspension polymerization of vinyl chloride monomer (VCM). The performance of PVC resin can be greatly optimized by selecting a suitable PVA grade with proper degree of polymerization and hydrolysis.

Emulsion Stabilizer & Binder

PVA can be widely used as protective colloid or thickener for the emulsion polymerization of vinyl acetate (VAc) or VAc/ acrylate. has the following characteristics: excellent adhesiveness;increased initial tack and drying rate while used with filler;excellent resistance to oiloutstanding film strength;enduring and stable performance.

Fiber fabrication

Two important applications of PVA is to be used as vinylon feedstock and sizing agent for textile.As raw material of vinylon fiber, has the advantages of being high in strength, moisture absorption, abrasion resistance,sunlight resistance, corrosion resistance and white in color. It can also be spun with cotton, wool and viscose fiber or purely spun with itself.As sizing agent for textile, It will not corrode or deteriorate with a good adhesion to cotton, hemp, polyester and viscose fiber.

Film

PVA can be used to produce water soluble film and water-resistance film. PVA is available in formed products which highlight the inherent features of PVA, namely, high tensile strength, resistance to organic solvent and air tightness.They are both widely used in the package industry, not only for textile, but also for chemicals, food, daily chemicals, agricultural chemicals, dyestuff, and etc.

Pulp & Paper

PVA has found wide use in the treatment of paper surface as it has excellent adhesiveness and dispersibility and will not affect the property of other binders used in combination. The advantages of PVA using:Surface strength (printability);Strength along Z-axis(paper internal strength);Folding resistance;Abrasive resistance;Improved smoothness;Improved surface glossiness;Raised resistance to oil and solvent (barrier property).

PVA Grades & Specifications

|

New Name |

Hydrolysis (mol%) |

Volatiles (%) |

Viscosity (mpa.s) |

Ash (wt%) |

PH Value |

Purity (wt%) |

|

088-03 |

87.0 – 89.0 |

≤5.0 |

3.0-4.0 |

≤0.7 |

5-7 |

≥93.0 |

|

088-04 |

87.0 – 89.0 |

≤5.0 |

4.0-4.5 |

≤0.7 |

5-7 |

≥93.0 |

|

098-04 |

98.0-98.8 |

≤5.0 |

4.0-5.0 |

≤0.5 |

5-7 |

≥93.5 |

|

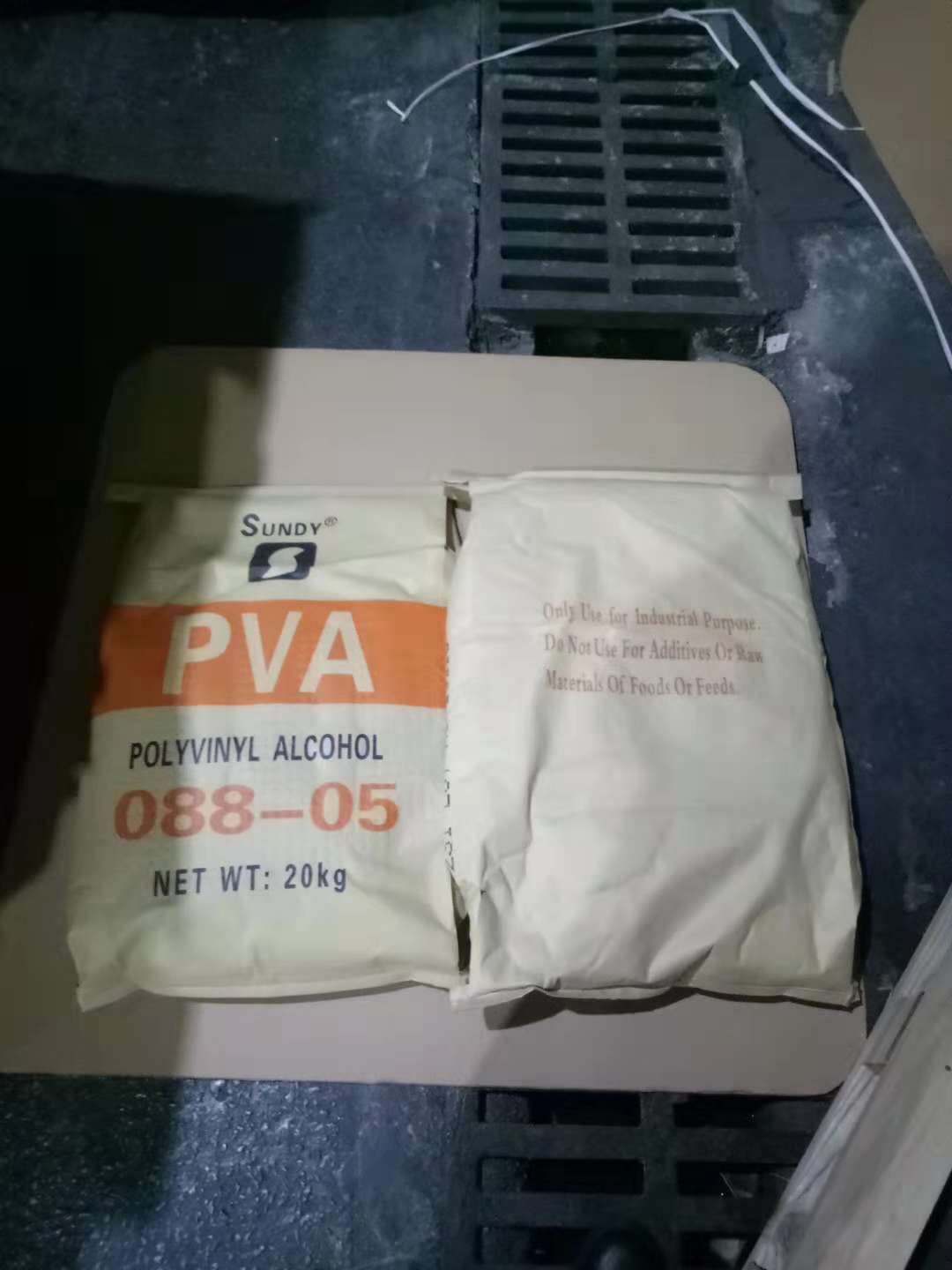

088-05 |

87.0 – 89.0 |

≤5.0 |

4.5-6.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-05 |

98.0-99.0 |

≤5.0 |

5.0-6.5 |

≤0.5 |

5-7 |

≥93.5 |

|

098-10 |

97.0-99.0 |

≤5.0 |

8.0-12.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-13 |

87.0 – 89.0 |

≤5.0 |

12.0-14.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-15 |

98.0 -99.0 |

≤5.0 |

13.0-17.0 |

≤0.5 |

5-7 |

≥93.5 |

|

093-16 |

92.5-94.5 |

≤5.0 |

14.5-18.5 |

≤0.5 |

5-7 |

≥93.5 |

|

098-20 |

98.0-99.0 |

≤5.0 |

18.0-22.0 |

≤0.5 |

5-7 |

≥93.5 |

|

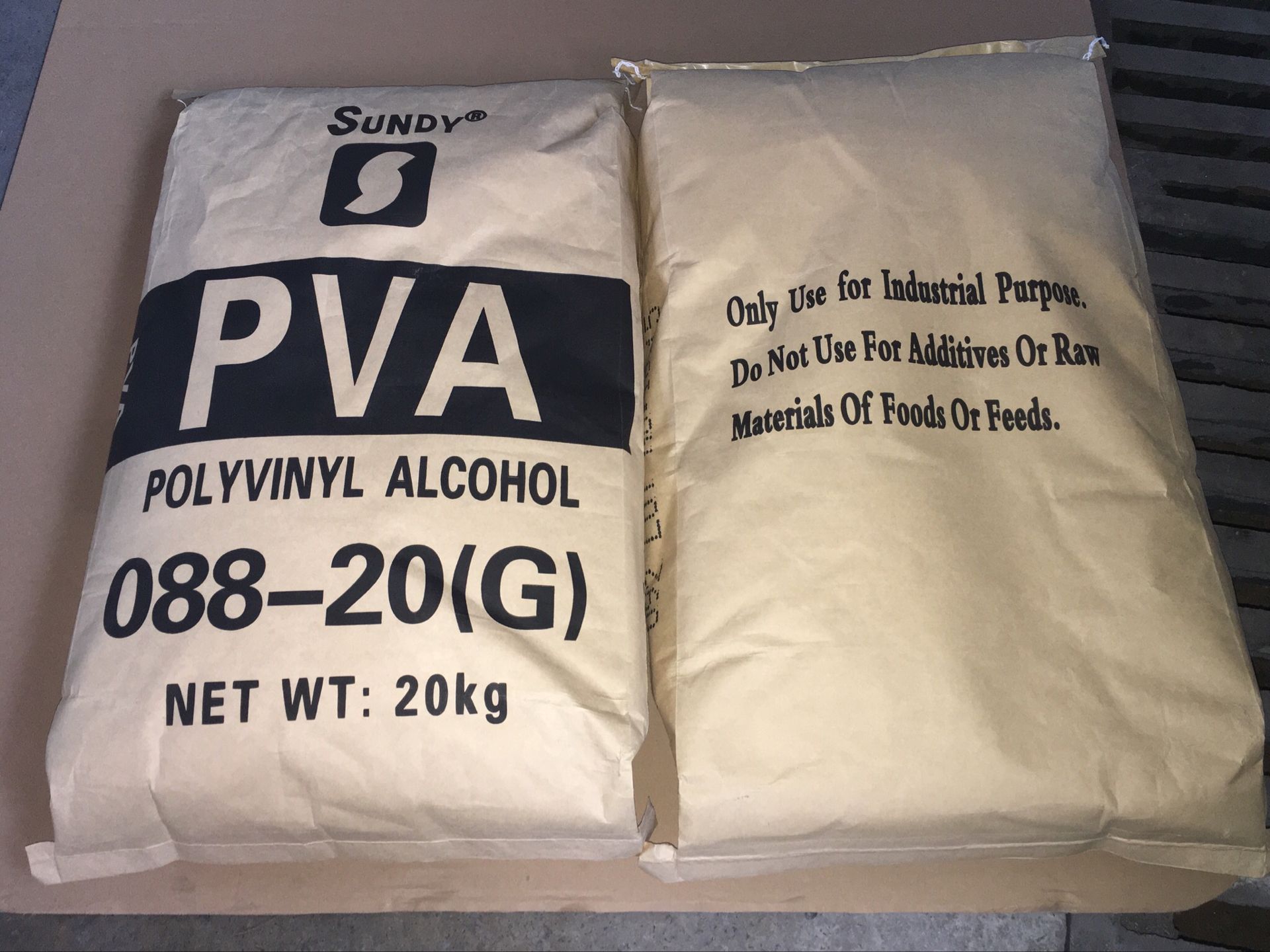

088-20 |

87.0 – 89.0 |

≤5.0 |

20.5-24.5 |

≤0.4 |

5-7 |

≥93.5 |

|

092-20 |

91.0-93.0 |

≤5.0 |

21.0-27.0 |

≤0.5 |

5-7 |

≥93.5 |

|

096-27 |

96.0-98.0 |

≤5.0 |

23.0-29.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-27 |

98.0 – 99.0 |

≤5.0 |

23.0-29.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-26 |

87.0 – 89.0 |

≤5.0 |

24.0-28.0 |

≤0.5 |

5-7 |

≥93.5 |

|

095-28 |

94.0-96.0 |

≤5.0 |

26.0-30.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-30 |

98.0 – 99.0 |

≤5.0 |

28.0-32.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-35 |

87.0 – 89.0 |

≤5.0 |

29.0-34.0 |

≤0.3 |

5-7 |

≥93.5 |

|

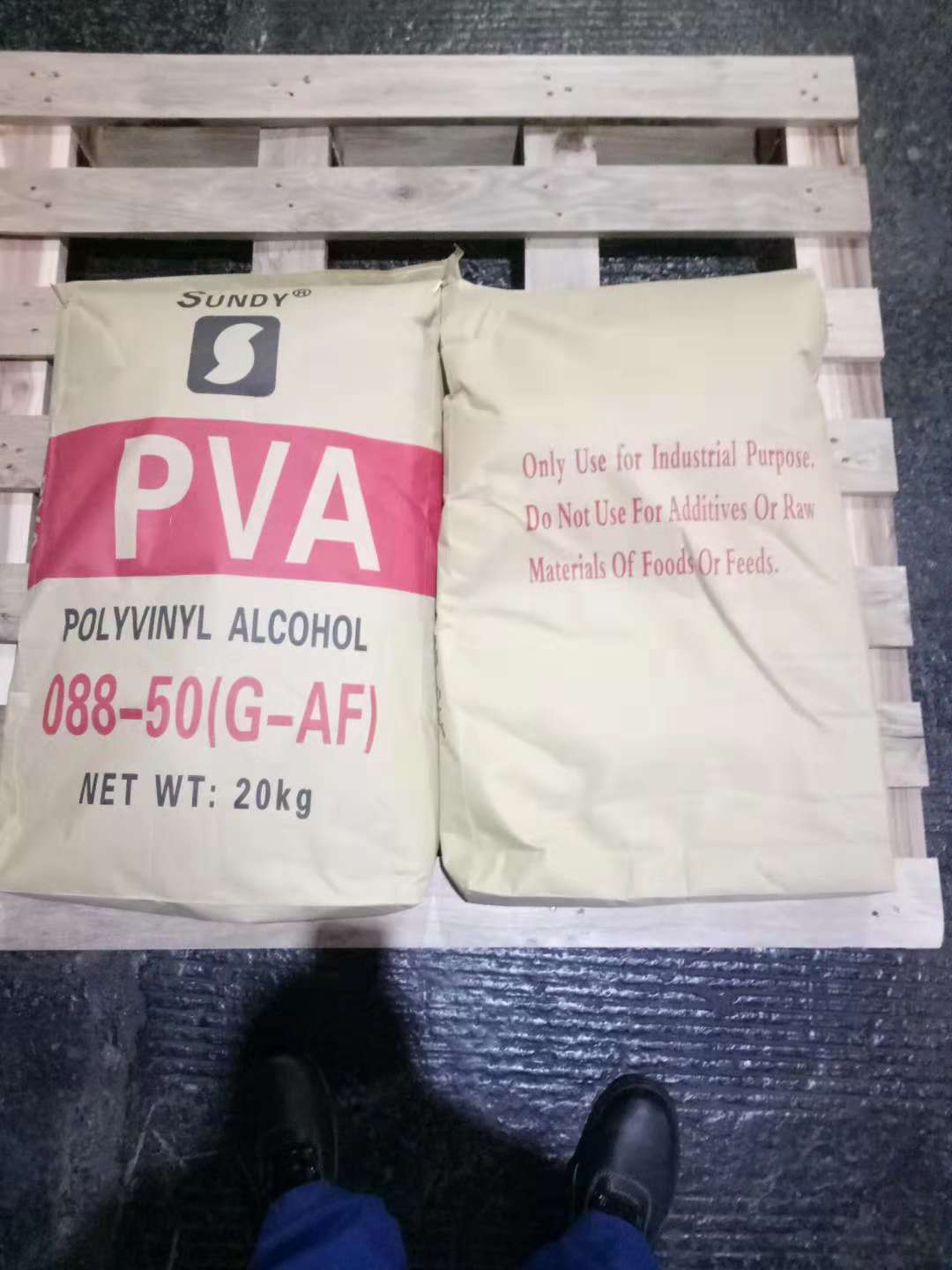

088-50 |

87.0 – 89.0 |

≤5.0 |

45.0-55.0 |

≤0.3 |

5-7 |

≥93.5 |

|

097-60 |

96.0-98.0 |

≤5.0 |

56.0-66.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-60 |

98.0 – 99.0 |

≤5.0 |

58.0-68.0 |

≤0.5 |

5-7 |

≥93.5 |

|

097-70 |

96.0 – 98.0 |

≤5.0 |

66.0-76.0 |

≤0.5 |

5-7 |

≥93.5 |

| 098-75 | 98.0 – 99.0 |

≤5.0 |

70.0-80.0 |

≤0.5 |

5-7 |

≥93.5 |

Product detail pictures:

Related Product Guide:

INTERVIEW: Xafinity Plc Now fifth largest UK pensions, actuarial, investment and administration business | Chinese Methyl Acrylate (Ma) Supplier

Smithers Rapra Technology Ltd : Quotes, Address, Contact | Chinese Pva Fiber Supplier

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for Factory source Pp Film Blowing Machine - Polyvinyl Alcohol – Haitung , The product will supply to all over the world, such as: Pretoria , Washington , Peru , Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We are looking forward to cooperating with friends from all over the world.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.