Newly Arrival Paraffin Wax For Candles - Polyvinyl Alcohol – Haitung

Newly Arrival Paraffin Wax For Candles - Polyvinyl Alcohol – Haitung Detail:

PRODUCER:SINOPEC

PVA has many exceptional properties such as water solubility, fiber-forming property, adhesiveness, film-forming property, emulsion stability, dispersion stability, resistance to oil, acid, and alkali, chemical reactivity, biodegradability, as well as meltability (or thermoplasticity) and many unique and special properties through modification.PVA is widely used in many industries like textile, papermaking, construction, chemicals, printing, packaging, pharmaceuticals, detergents & cosmetics, agriculture, ceramics, iron & steel, electronics, electrolysis, electroplating, and etc.

Application:

PVA, which is excellent in colloid protection and has superior surface activity, is often used as dispersion stabilizer for suspension polymerization of vinyl chloride monomer (VCM). The performance of PVC resin can be greatly optimized by selecting a suitable PVA grade with proper degree of polymerization and hydrolysis.

Emulsion Stabilizer & Binder

PVA can be widely used as protective colloid or thickener for the emulsion polymerization of vinyl acetate (VAc) or VAc/ acrylate. has the following characteristics: excellent adhesiveness;increased initial tack and drying rate while used with filler;excellent resistance to oiloutstanding film strength;enduring and stable performance.

Fiber fabrication

Two important applications of PVA is to be used as vinylon feedstock and sizing agent for textile.As raw material of vinylon fiber, has the advantages of being high in strength, moisture absorption, abrasion resistance,sunlight resistance, corrosion resistance and white in color. It can also be spun with cotton, wool and viscose fiber or purely spun with itself.As sizing agent for textile, It will not corrode or deteriorate with a good adhesion to cotton, hemp, polyester and viscose fiber.

Film

PVA can be used to produce water soluble film and water-resistance film. PVA is available in formed products which highlight the inherent features of PVA, namely, high tensile strength, resistance to organic solvent and air tightness.They are both widely used in the package industry, not only for textile, but also for chemicals, food, daily chemicals, agricultural chemicals, dyestuff, and etc.

Pulp & Paper

PVA has found wide use in the treatment of paper surface as it has excellent adhesiveness and dispersibility and will not affect the property of other binders used in combination. The advantages of PVA using:Surface strength (printability);Strength along Z-axis(paper internal strength);Folding resistance;Abrasive resistance;Improved smoothness;Improved surface glossiness;Raised resistance to oil and solvent (barrier property).

PVA Grades & Specifications

|

New Name |

Hydrolysis (mol%) |

Volatiles (%) |

Viscosity (mpa.s) |

Ash (wt%) |

PH Value |

Purity (wt%) |

|

088-03 |

87.0 – 89.0 |

≤5.0 |

3.0-4.0 |

≤0.7 |

5-7 |

≥93.0 |

|

088-04 |

87.0 – 89.0 |

≤5.0 |

4.0-4.5 |

≤0.7 |

5-7 |

≥93.0 |

|

098-04 |

98.0-98.8 |

≤5.0 |

4.0-5.0 |

≤0.5 |

5-7 |

≥93.5 |

|

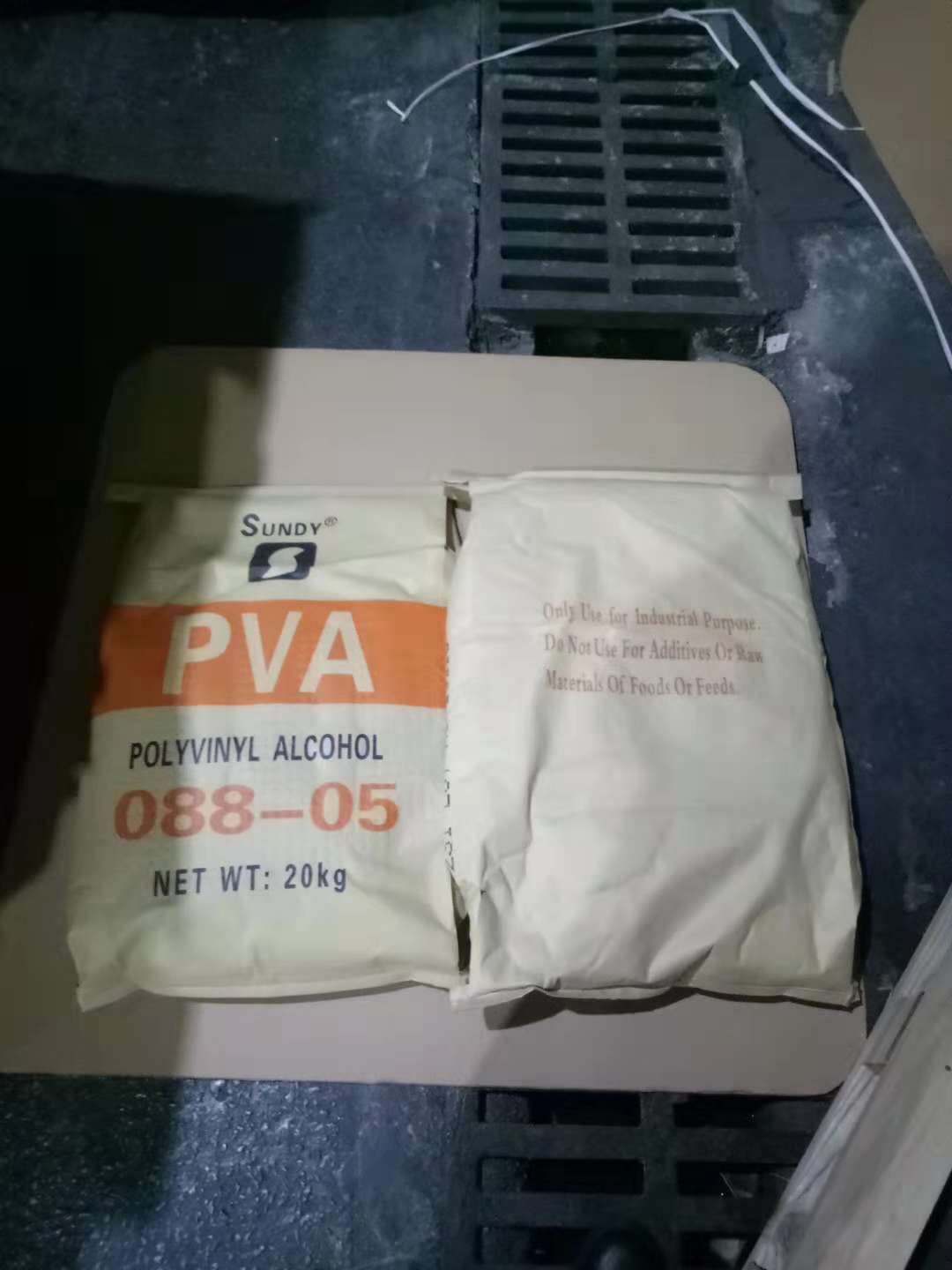

088-05 |

87.0 – 89.0 |

≤5.0 |

4.5-6.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-05 |

98.0-99.0 |

≤5.0 |

5.0-6.5 |

≤0.5 |

5-7 |

≥93.5 |

|

098-10 |

97.0-99.0 |

≤5.0 |

8.0-12.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-13 |

87.0 – 89.0 |

≤5.0 |

12.0-14.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-15 |

98.0 -99.0 |

≤5.0 |

13.0-17.0 |

≤0.5 |

5-7 |

≥93.5 |

|

093-16 |

92.5-94.5 |

≤5.0 |

14.5-18.5 |

≤0.5 |

5-7 |

≥93.5 |

|

098-20 |

98.0-99.0 |

≤5.0 |

18.0-22.0 |

≤0.5 |

5-7 |

≥93.5 |

|

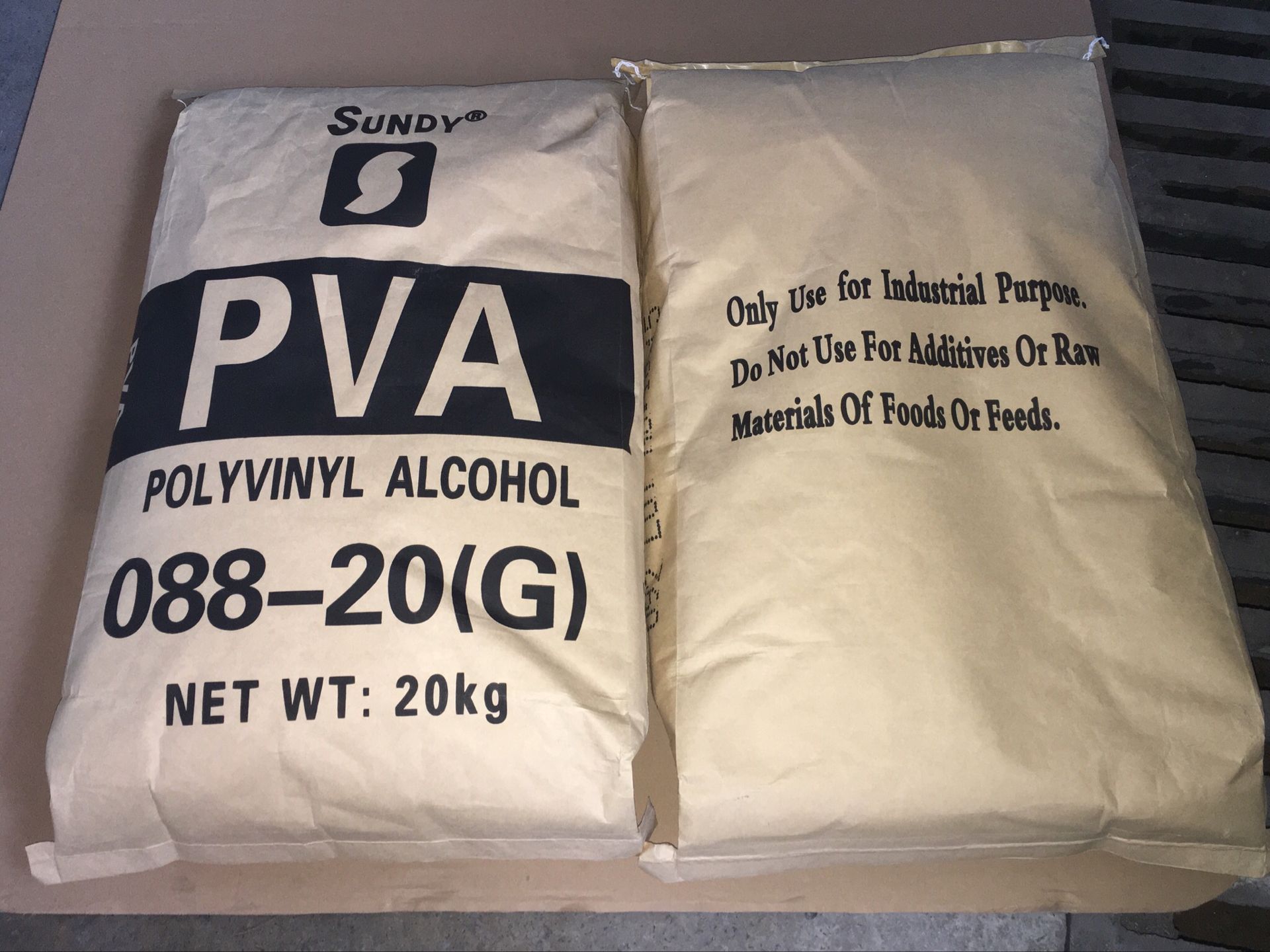

088-20 |

87.0 – 89.0 |

≤5.0 |

20.5-24.5 |

≤0.4 |

5-7 |

≥93.5 |

|

092-20 |

91.0-93.0 |

≤5.0 |

21.0-27.0 |

≤0.5 |

5-7 |

≥93.5 |

|

096-27 |

96.0-98.0 |

≤5.0 |

23.0-29.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-27 |

98.0 – 99.0 |

≤5.0 |

23.0-29.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-26 |

87.0 – 89.0 |

≤5.0 |

24.0-28.0 |

≤0.5 |

5-7 |

≥93.5 |

|

095-28 |

94.0-96.0 |

≤5.0 |

26.0-30.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-30 |

98.0 – 99.0 |

≤5.0 |

28.0-32.0 |

≤0.5 |

5-7 |

≥93.5 |

|

088-35 |

87.0 – 89.0 |

≤5.0 |

29.0-34.0 |

≤0.3 |

5-7 |

≥93.5 |

|

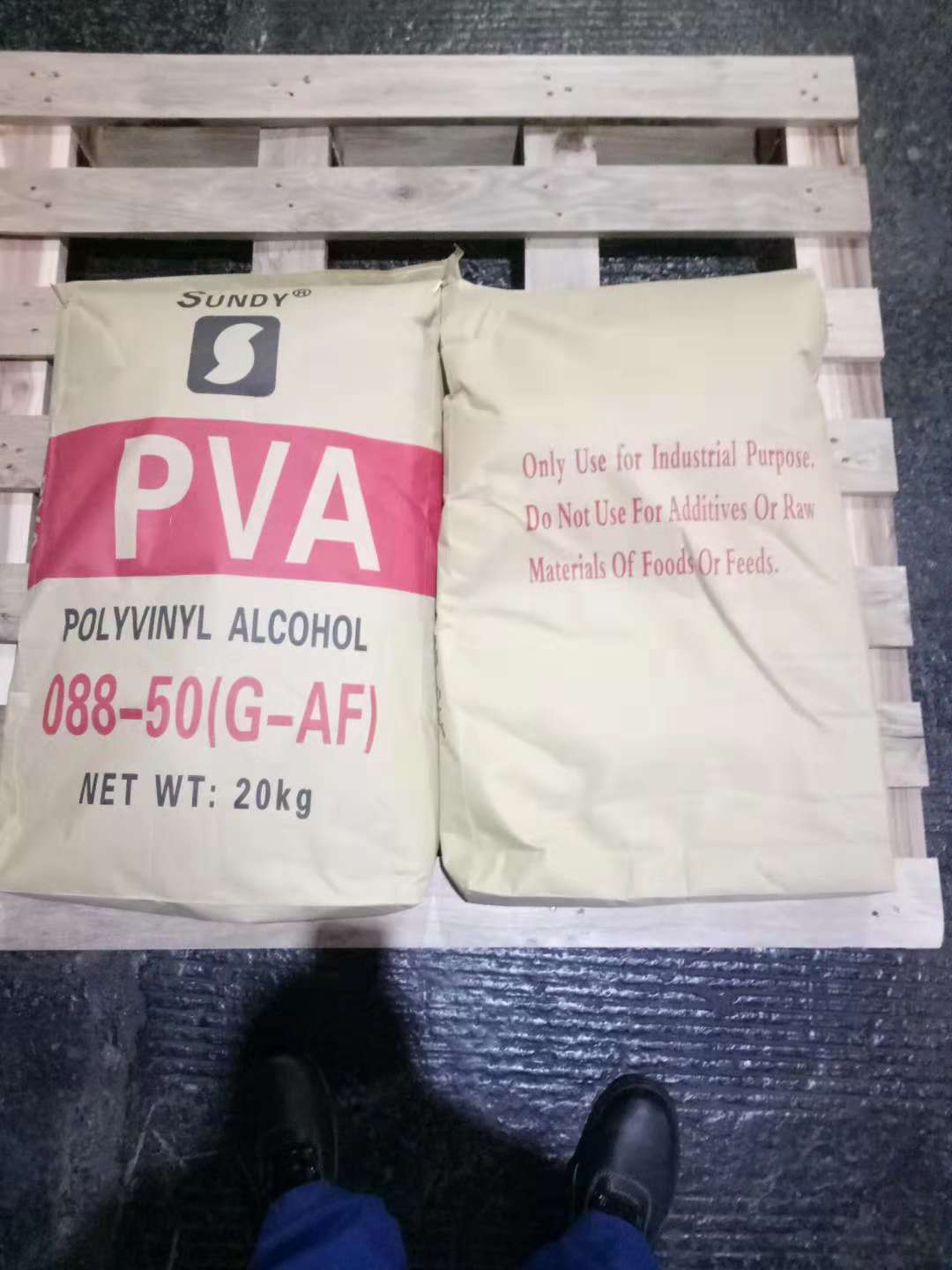

088-50 |

87.0 – 89.0 |

≤5.0 |

45.0-55.0 |

≤0.3 |

5-7 |

≥93.5 |

|

097-60 |

96.0-98.0 |

≤5.0 |

56.0-66.0 |

≤0.5 |

5-7 |

≥93.5 |

|

098-60 |

98.0 – 99.0 |

≤5.0 |

58.0-68.0 |

≤0.5 |

5-7 |

≥93.5 |

|

097-70 |

96.0 – 98.0 |

≤5.0 |

66.0-76.0 |

≤0.5 |

5-7 |

≥93.5 |

| 098-75 | 98.0 – 99.0 |

≤5.0 |

70.0-80.0 |

≤0.5 |

5-7 |

≥93.5 |

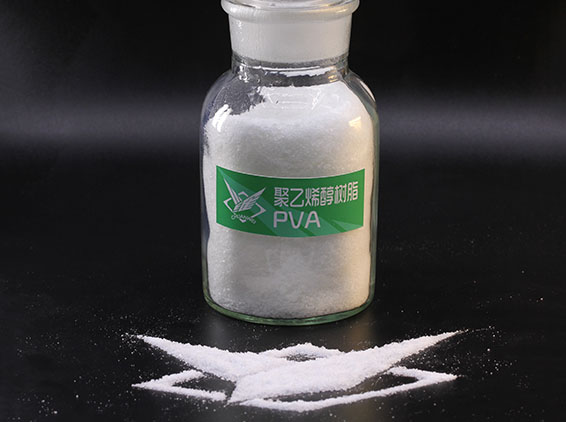

Product detail pictures:

Related Product Guide:

People & Places: FIBBR Joins PVA; Legrand Acquires Kenall; StormAudio Joins Azione; Lau Wyrestorm | Vinyl Acetate Icis Report

Polyvinyl Alcohol (PVA) Films Market by Key Players: Aicello Chemicals, Jiangmen Proudly Water Soluble Plastic Co, Changzhou Water Soluble Co Ltd. – Press Release | Chinese Pva Fiber Supplier

We can always satisfy our respected customers with our good quality, good price and good service due to we are more professional and more hard-working and do it in cost-effective way for Newly Arrival Paraffin Wax For Candles - Polyvinyl Alcohol – Haitung , The product will supply to all over the world, such as: Swedish , Estonia , Italy , Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly