Professional Design Cas 1070-70-8 1 4-butanediol Diacrylate - SEBS(Styrene Ethylene Butylene Styrene) – Haitung

Professional Design Cas 1070-70-8 1 4-butanediol Diacrylate - SEBS(Styrene Ethylene Butylene Styrene) – Haitung Detail:

PROPERTIES AND APPLICATIONS

Styrene-ethylene-butylene-styrene, also known as SEBS, is an important thermoplastic elastomer (TPE) which behaves like rubber without undergoing vulcanization.SEBS is strong and flexible, has excellent heat and UV resistance and is easy to process. It is produced by partial and selective hydrogenating of styrene-butadiene-styrene copolymer (SBS) which improves the thermal stability, weathering and oil resistance, and makes SEBS steam sterilisable.However, hydrogenation also reduces the mechanical performance and increases the cost of the polymer.

SEBS elastomers are often blended with other polymers to enhance their performance. They are used as impact modifiers for engineering thermoplastics and as flexibilizers / tougheners for clear polypropylene (PP).Often oil and fillers are added to lower cost and / or to further modify the properties. Important applications include hot-melt pressure sensitive adhesives, toy products, shoe soles, and TPE-modified bitumen products for road paving and roofing applications.

Styrenics, or styrenic block copolymers are the most widely used of all TPE’s. They combine well with other materials as well as fillers and modifiers. SEBS (styrene-ethylene/butylene-styrene) is characterized by hard and soft domains within individual polymer strands. The end-blocks are crystalline styrene while the mid-blocs are soft ethylene-butylene blocks. At higher temperatures these materials soften and become fluid. When cooled, the strands join at the styrene end-blocks forming a physical cross-link and providing a rubber like elasticity. Clarity and FDA approval make SEBS an excellent option for high-end applictions.

Adhesives And Sealants And Coatings

SEBS can improve performance in pressure-sensitive and other adhesive applications. Some of the more common applications include a variety of tapes, labels, plasters, construction adhesives, medical dressings, sealants, coatings and road marking paints.

Compounds

SEBS can be compounded to produce materials which improve the grip, feel, appearance and convenience of various applications. Sports and leisure, toys, hygiene, packaging, automotive, and molded and extruded technical goods are some common examples.

SEBS can be used in combination with various fillers. Compounders will add these fillers if enhanced oil absorption, cost reduction, improved surface feel, or additional stabilization is required over pure SEBS.

Probably the most common filler for SEBS is oil. These oils will be chosen depending on specific application requirements. Adding aromatic oil softens the PS blocks by plasticizing which decreases hardness and physical properties. Oils make the products softer and also act as processing aids. Paraffinic oils are preferred because they are more compatible with the EB center block. Aromatic oils are generally avoided because they intrude into and plasticize the polystyrene domains.

Packaging And Polymer Modification

SEBS can enhance high styrene applications, films, bags, stretch film and disposable packaging. They can improve the performance of polyolefins for use in extreme temperatures, improve clarity and scratch resistance, and enhance elasticity.

Main Properties of Each Grade of SEBS Series Products (Typical Value)

| Grade | Structure | Block Ratio | 300% Stretching Strength MPa | Ensile Strength MPa | Elonga tion % | Permanent Set % | Hardness Shore A | Toluene Solution Viscosity at 25℃ and 25%, mpa.s |

| YH-501/501T | Linear | 30/70 | 5 | 20.0 | 490 | 24 | 76 | 600 |

| YH-502/502T | Linear | 30/70 | 4 | 27.0 | 540 | 16 | 73 | 180 |

| YH-503/503T | Linear | 33/67 | 6 | 25.0 | 480 | 16 | 74 | 2,300 |

| YH-504/504T | Linear | 31/69 | 5 | 26.0 | 480 | 12 | 74 | |

| YH-561/561T | Mixed | 33/67 | 6.5 | 26.5 | 490 | 20 | 80 | 1,200 |

| YH-602/602T | Star-shaped | 35/65 | 6.5 | 27.0 | 500 | 36 | 81 | 250 |

| YH-688 | Star-shaped | 13/87 | 1.4 | 10.0 | 800 | 4 | 45 | |

| YH-604/604T | Star-shaped | 33/67 | 5.8 | 30.0 | 530 | 20 | 78 | 2,200 |

Note: The toluene solution viscosity of YH-501/501T is 20%, and that of others is 10%.

“T” means desalted water.

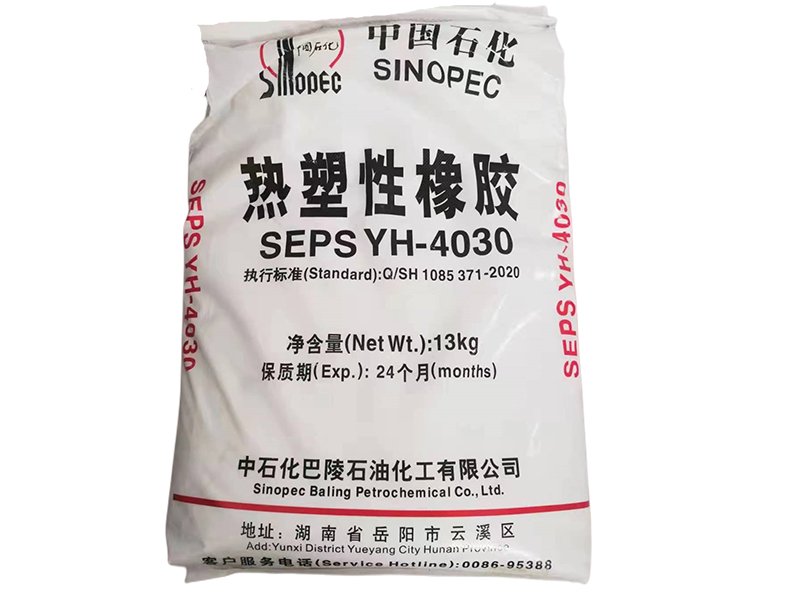

Product detail pictures:

Related Product Guide:

Italdenim eco-friendly denim processed with chitosan | Apparel Industry News | Chinese Pva Fiber Supplier

Market Risers: Plant Health Care plc, Oncimmune Holdings PLC, Powerhouse Energy Group PLC & Predator Oil & Gas Holdings PLC | Chinese Methyl Acrylate (Ma) Supplier

We emphasize advancement and introduce new products and solutions into the market each year for Professional Design Cas 1070-70-8 1 4-butanediol Diacrylate - SEBS(Styrene Ethylene Butylene Styrene) – Haitung , The product will supply to all over the world, such as: Jordan , Finland , Cancun , Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.